The present-day business landscape is marked by demanding customers, expecting impeccable product quality, superior service and instantaneous deliveries, and rapid tech advancements that are shaping it. Companies actively navigate the maze of uncertainties and challenges to stay competitive and meet consumer demands. The role of warehousing is vital in this landscape. Nowadays, warehousing is no longer a mere logistical element. It's a strategic cornerstone for companies operating in dynamic markets.

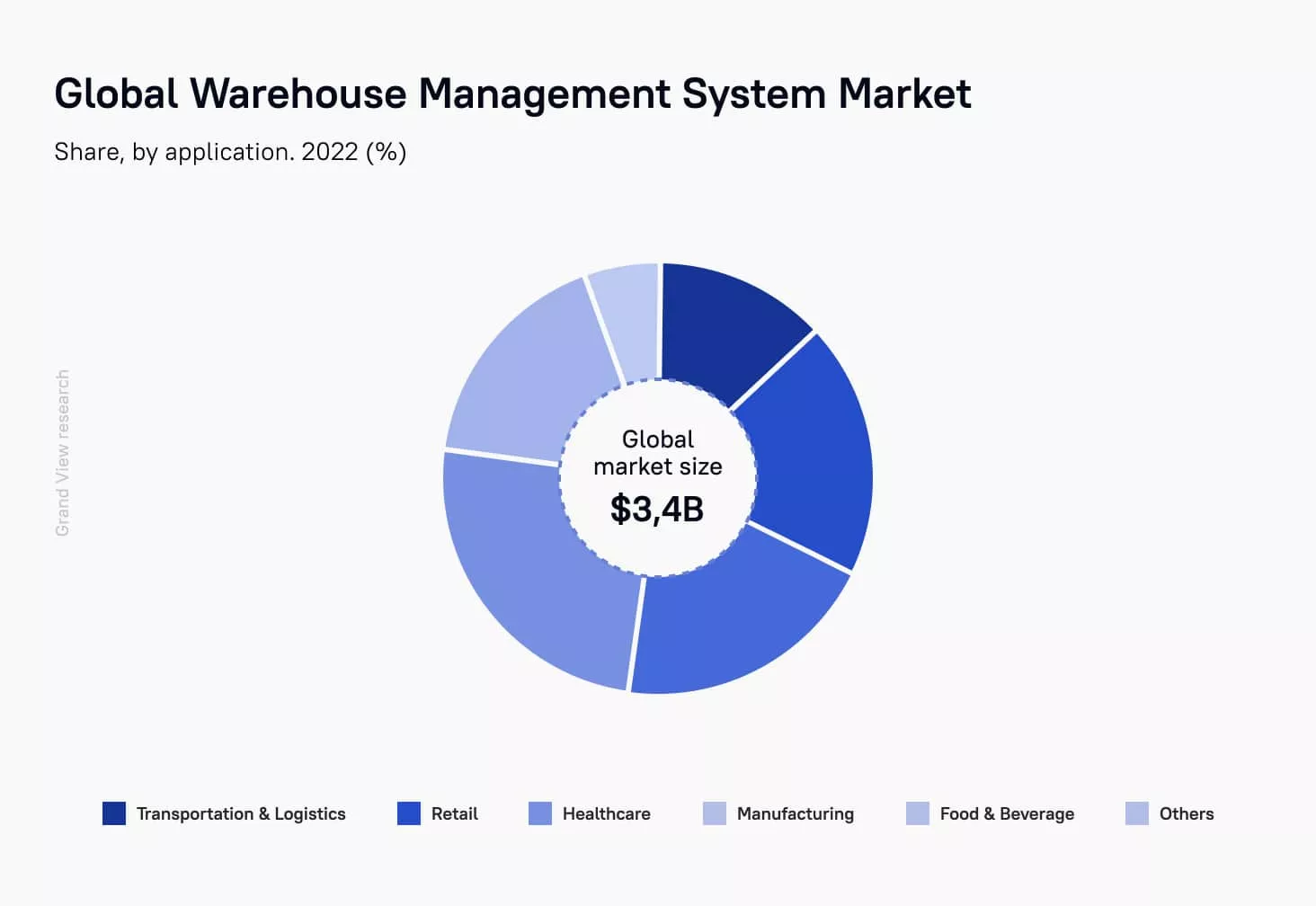

The Global Newswire report states that the global WMS market size is recording a CAGR of 17.3% from 2023 to 2030. By 2030 it is expected to reach $51.36 billion, in 2022 this figure was 3.5 times less -$14.51 billion.

So, today we are going to spill the beans on how warehouse management systems can revolutionize business operations and drive operational efficiency.

Let’s start from the basics.

What Is a Warehouse Management Solution, and How Does it Work?

A WMS allows companies to control, administer, and accurately track their goods and materials from the moment they arrive at the warehouse till they leave it being sent to recipients. Warehouse management systems provide greater visibility into a company’s inventory. They facilitate managing warehouses and supply chain procedures. They help to ensure that the packages reach their destinations on time or even faster. The systems streamline the process of orders receiving, inspecting, picking up, storing, and packing.

WMS software enables companies to optimize their operations. Thus, they improve efficiency and achieve a wide range of extra benefits.

WMS systems contain a wide range of data that is intended to optimize warehouse processes. When an order is placed, the system can determine if the product is available. It's done by reviewing the up-to-date inventory. It marks it as ready for packing if found in stock. This relieves the workers and saves time and effort significantly.

Want a web app that does more?

Let's build a solution that's smart, sleek, and powerful.

Alina

Client Manager

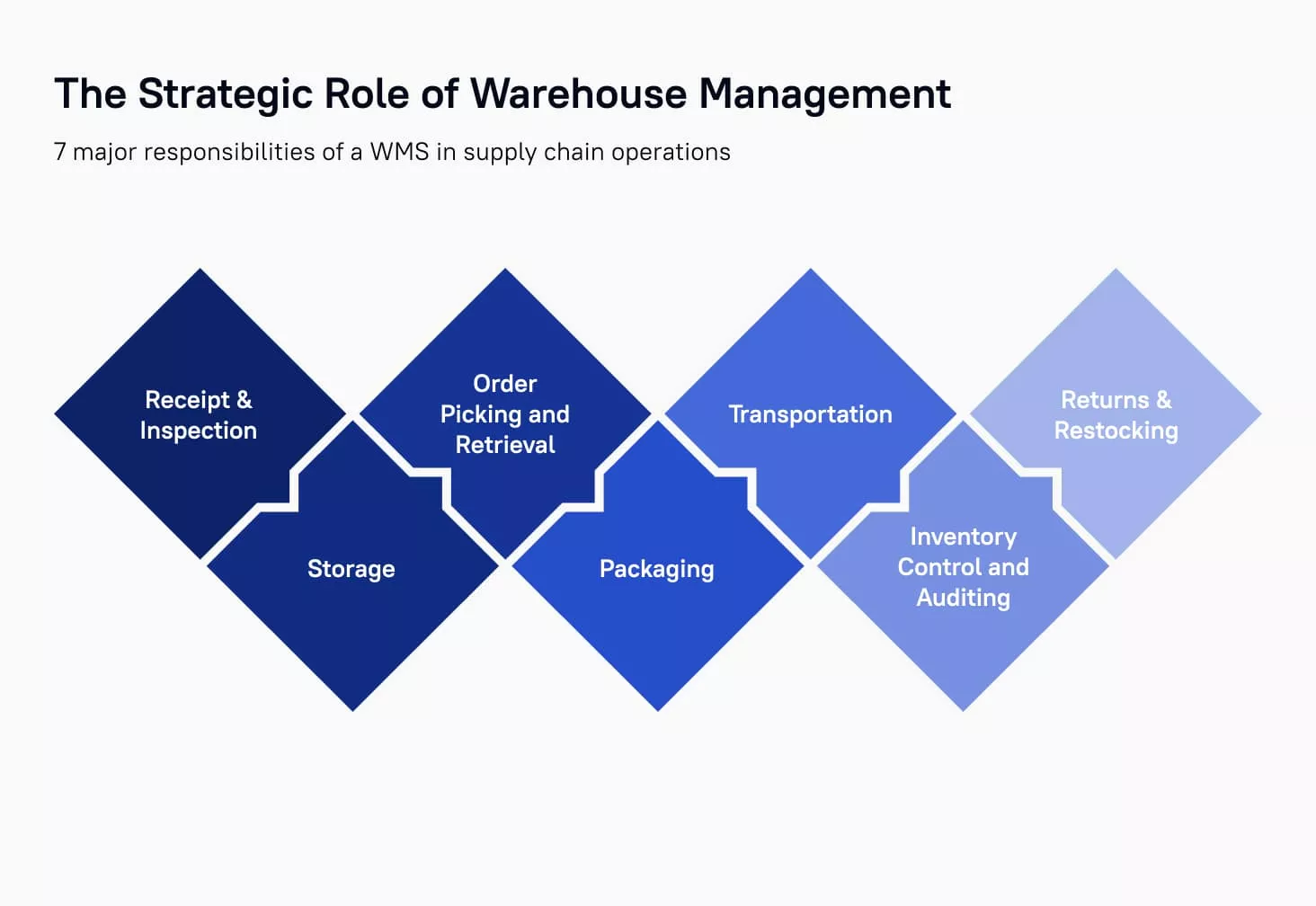

The Strategic Role of Warehouse Management

The efficient management of a supply chain can guarantee an uninterrupted flow of goods for businesses. Many factors can disrupt the supply chain and result in delivery delays. However, risks can be reduced if innovative tools are integrated. Let’s look at the 7 major responsibilities of a WMS in supply chain operations.

1. Receipt & Inspection

Proper management at a warehouse starts with the receiving and inspection of the materials and goods that arrive. The pallets should be inspected to ensure that the products have not been damaged or lost during transit. In case of inconsistencies, a new purchase order should be placed to solve them.

With a WMS, inbound and outboard logistics can be optimized. The first step can be to optimize scheduling and tools for the employees when new inventory is expected.

2. Storage

Products received are transported to a designated location for storage. It’s vital to cautiously choose a place to store goods. They should remain secure, without any damage, and often in a temperature-controlled environment. A good WMS can determine the most effective use of space and human effort to reduce operation costs. What is more, you can create a floor plan of your storage and the system will analyze it to determine where to store materials and goods best.

3. Order Picking and Retrieval

The next step is to pick an order when it’s placed by a customer. The pickers should be accurate to make sure the right product of the right size and color is quickly brought to the packing location. To relieve this tension, a WMS can offer you enhanced visibility of the goods in stock through serial numbers, barcoding, and RFID tagging. So, you can access this real-time data as to the inventory available at any time.

Additionally, a WMS can be used to forecast what is popular among the customers during different times of the year.

4. Packaging

Packaging today is not any more basic envelopes and boxes. They are now complex systems that allow products to transit quickly along a global supply chain. Lots of companies look for new ways to package more efficiently, cost-effectively, and with better design. Your WMS can facilitate a better-organized packaging process through enhanced labeling and traceability.

5. Transportation

Efficient logistics and asset management are the basis for supply chain effectiveness. One should ensure the best usage of the containers, vehicles, and supplementary assets for the most efficient logistics execution.

A WMS solution can generate and send bills of lading (B/L), generate packing lists and invoices for customers, and even assemble instructions in case of need. The software can also send ASNs (advanced shipment notifications) to warn other facilities of pending deliveries and keep all the parties involved in the supply chain informed on the status of packages in transit.

6. Inventory Control and Auditing

These are the important elements of warehouse management that prevent costly problems if small inventory errors occur or damaged products are found. Audits are usually performed with varied frequency. It is determined by the warehouse's overall size and operational complexity. The current inventory levels are compared to data in the system to ensure all the details align and expiration dates have not passed. Auditing in WMS may include personnel performance assessment, strategies scheduling, and forecasting.

7. Returns & Restocking

Returns and restocking are often the areas that cause companies to fall behind. Being the critical elements of warehouse management, they influence customer service directly. There is always a chance that a customer may return the order. Warehouse personnel should provide seamless and effective ‘return management’ or reverse logistics within the supply chain for such cases. A WMS can make the process of receiving the products back and restocking, as well as picking and packing exchanges, more efficient through a system of timely notifications.

Who Can Benefit from Warehouse Management Software Development?

WMS can become a secret weapon for any retail business because it can help you keep your shelves full and customers satisfied. A properly adjusted system will prevent you from seasonal and not-only out-of-stock nightmares. A warehouse management system can check your inventory regularly so that your buyers can find whatever they want. That should likely increase your sales.

The best warehouse management system for e-commerce serves as a go-to solution for hassle-free order management. The software can streamline all the processes from packing to shipment to the satisfaction of your customers. WMS for e-commerce can help you outcompete your rivals and be ranked 5 stars.

Manufacturers can make wonders with a WMS being their magic stick. It allows seamless operations and tracking of raw materials, products, goods, and everything that falls in between.

For Wholesale business, a WMS can become a trusty partner. It will ensure all the inventory is in top shape and help you avoid costly mistakes and over- or under-ordering.

So, we hope we have persuaded you that a WMS can add value to any sector and various businesses. Stfalcon stands the ground of software customization. Let’s discuss the advantages of custom warehouse management software development!

What Are the Benefits of Warehouse Management Software Customization?

Warehouse managing systems are sometimes called the fuel powering business operational efficiency. They can automate and fine-tune operations along the supply chain. Warehouse inventory systems optimize space utilization, and simplify stock location tracking. It makes any item just a click away.

Crafting a custom solution is always a way to tailor the unique software for your specific business, processes, operations, needs, and peculiarities. The best warehouse management system for a small business or large-scale corporation can take the needs of a specific company into account. It can boost its productivity, optimize resources, and slash overheads.

With a custom-developed WMS, you get

- Flexibility. While standard WMS systems offer only general features, a customized product surpasses the limitations of the standard functionality. More than that, it can undergo multifaceted integrations whenever it’s required.

- Specific Features and Unique Capabilities. A simple WMS system has predefined features and operations that may not be of use to your company or not align with the business goals you set. A custom-created software comprises functionality designed to meet your business objectives.

- Scalability and Growth. A standard WMS has limited capabilities and might struggle to fit the requirements of the business that expands. With a custom solution, you can adapt to the actual workflows, incorporate new features, integrate new tools, and expand the whole system if it’s needed.

- Productivity and Efficiency. A custom WMS allows better workflow optimization and process automation. It results in error reduction, better productivity, fewer bottlenecks, and smooth overall operation.

- Cost Savings. They are a logical result of reduced manual labor and human errors, lower operational costs, and process optimization.

- Enhanced Security. When developing a custom solution, you can protect your data and inventory from unauthorized access. You can achieve this by implementing the most vigorous security features.

- Multiple Integration Opportunities. Since you know the needs of your business and warehouse processes the best, you can integrate your custom WMS with either your existing systems or with the tools you consider useful. Thus, you can ensure smooth communication within the company between different departments.

Hope we have dispelled your doubts as to the benefits of a custom WMS system for small business development. Big companies that can afford it simply go without saying.

To draw a line, we’ll mention that by tailoring custom software to suit your business requirements, you can optimize warehouse operations, decrease costs, and bring efficiency to the next level.

Why Choose Stfalcon as Your Best Vendor?

Stfalcon has been operating in the market of software development for over 15 years. We have been regularly acknowledged as the Ukrainian best developer and app developer by Clutch. We have recently completed our management system certification and are now compliant with ISO 9001:2015 requirements. We had to restructure our existing and introduce some additional documentation. Most importantly we established precise internal quality standards, set up a regular performance review schedule for our teams, refined our reporting format, and implemented a performance improvement mechanism as mandated by ISO.

Having successfully carried out over 324 projects all over the world, we have profound expertise in many fields and logistics and supply chain software development in particular. So, if you are looking for a trusted vendor, Stfalcon is your best choice.

Final Word

By developing a custom warehouse management system, you can bring order and gain control over all the procedures. This invisible hand can help you avoid redundant steps, minimize errors, and optimize and automate processes, thus fueling productivity, increasing efficiency, and at the same time saving costs.

With a custom WMS, you can solve even the most complex and nuanced issues, because you can tailor the software exactly to meet your business needs. At Stfalcon we know how to craft cutting-edge products that exceed the expectations of our clients. We are ready to do it for you, just contact us to discuss the details.