With 2026 around the corner, geopolitics poses the biggest threat to global supply chains. Wars and political instability disrupt trade routes and make logistics harder everywhere around the globe.

The russian invasion of Ukraine in early 2022 trapped nearly 100 ships with foreign crews in Ukrainian ports. In late 2023, Houthi attacks in the Red Sea forced commercial vessels to detour around Africa, adding weeks to delivery times. Then came the tariff rollercoaster of 2025, when Donald Trump introduced reciprocal U.S. tariffs, paused them for most countries, and reignited uncertainty across global markets.

Such constant disruptions demand resiliency from logistics companies, but when operations still rely on calls, emails, and spreadsheets, it’s hard to keep up. Today’s logistics requires custom software solutions tailored to each business. Here’s what it can offer for your business to survive the modern market challenges.

TL;DR

Fragmented systems and manual processes can't keep up with global logistics challenges. To stay resilient, companies need integrated software built around their operations. In this article, you'll discover a list of supply chain risks and how to mitigate them:

- Custom software helps companies overcome supply chain challenges and disruptions.

- Why custom systems for logistics and transportation outperform off-the-shelf solutions.

- How AI agents can automate workflows, predict supply chain risks, and optimize costs.

- The “right experience” for B2C and B2B logistics customers and why speed and visibility matter.

- Real-world case studies showing measurable business results from custom logistics software.

- How to balance technology vision, automation, and budget for your software project.

Supply chain challenge 1. Disconnected systems block visibility → integration brings it back

Most freight operations run on a patchwork of systems: one for dispatch, another for warehouse management, a third for tracking, and someone's personal notebook for "special customer notes."

This fragmentation creates blind spots in the supply chain. Dispatchers don’t see maintenance schedules, sales can’t check real-time capacity, and teams waste hours re-entering data into several disconnected systems.

Why accept these inefficiencies when integrated software can eliminate them?

Custom software connects all these tools into a single system tailored to your operations. Depending on your niche in logistics and transportation, you can build:

Transportation management system (TMS)

Works best for: logistics providers, shippers, and freight forwarders.

A custom TMS looks different for every company, but the idea’s the same: it automates your core workflows, including dispatch, routing, billing, carrier, and load management. You can also add real-time weather data, freight cost analytics, or any feature your business needs.

Supply chain management (SCM) software

Works best for: manufacturers, distributors, and retailers that coordinate end-to-end supply chains.

SCM software handles the entire product flow, which is why it often includes TMS, fleet management, and delivery tools as modules. It helps reduce supply chain management risks and challenges by connecting procurement, warehousing, forecasting, and supplier coordination, so you don’t have to manage these pieces separately.

Fleet management system (FMS)

Works best for: transportation, construction, and service companies that operate fleets.

FMS is a great tool to handle fleets. It usually combines vehicle tracking, maintenance scheduling, fuel management, driver performance monitoring, and compliance reporting in a single system. As extras, you can also have predictive maintenance, compliance reporting, or sustainability tracking. As they say, anything you want, as long as you pay for it.

Order & delivery management software

Works best for: ecommerce, retail, and logistics companies.

If your company delivers products to customers, you know every business handles orders differently. Some process them through multiple warehouses, others ship directly from stores. That’s why a one-size-fits-all system doesn’t work. You need a custom-built order and delivery management solution that matches your exact process, connecting sales, warehouse, and delivery into one flow.

| System type | What it covers | Basic features |

|---|---|---|

| TMS | Transportation operations and freight movement |

• Dispatch and route planning • Load and carrier management • Freight billing and cost control • Real-time shipment tracking • Optional: weather data, analytics, custom reports |

| SCM | Full product flow from supplier to customer |

• Procurement and supplier management • Inventory and warehouse control • Demand forecasting • Order tracking and fulfillment • Can include TMS, FMS, and delivery modules |

| FMS | Fleet and vehicle operations |

• GPS vehicle tracking • Maintenance scheduling • Fuel usage monitoring • Driver performance tracking • Extras: predictive maintenance, sustainability tools |

| Order & delivery software | Customer order handling from placement to delivery |

• Order processing and fulfillment • Warehouse and sales sync • Delivery scheduling and tracking • Customer notifications and updates • Flexible workflows and custom integrations |

Of course, none of these systems exist in a vacuum. So when you build custom logistics software, make sure it integrates with your ERP, CRM, and current tech stacks.

Challenge 2. Your system is too slow to adapt → AI makes your operations resilient and dynamic

It's not like logistics companies aren’t responsive to sudden disruptions or changes. But these responses are slow. When a truck gets stuck in traffic or a shipment misses its delivery window, dashboards light up with red alerts. A dispatcher then calls the driver, checks alternative routes, contacts the warehouse, and finally relays instructions. Each step takes time, and in the fast-moving logistics industry, those delays mean missed deliveries and higher costs.

That's the problem: visibility without automation doesn't build resilience. When logistics change by the hour, you need systems that react instantly. Or even better, predict what’s coming.

AI gives you that edge. If the system detects a blocked route or a closed channel, it can automatically reroute a ship or truck. And that’s just one example.

AI agents can handle dozens of similar tasks, like forecasting demand, optimizing routes, scheduling maintenance, or managing customer updates. And these guys (aka your tireless AI agents) don’t wait for human input.

| Demand forecasting agent ↓

Predicts inventory needs and customer demand

| Maintenance agent ↓

Schedules repairs and monitors vehicle health

| Customer experience agent ↓

Sends shipment updates and handles inquiries

|

| Cost optimization agent ↓

Spots cost leaks in routes, fuel, and labor, and recommends smarter options

| Shipment tracking agent ↓

Provides real-time updates and alerts for delivery issues

| Risk & disruption agent ↓

Identifies potential delays from weather, traffic, or other disruptions

|

If you think AI is only “for the chosen” with huge budgets, think again. Cloud AI services and pre-built models have made automation far more affordable than it was in 2020. Today, any mid-market logistics company planning custom software can integrate AI agents to streamline operations. The real advantage shows when companies decide to act rather than wait.

Read our article: 7 AI Use Cases Transforming Modern Logistics.

Take C.H. Robinson, a global logistics and supply chain company. They deployed over 30 AI agents at scale across their global network, automating more than 3 million shipping tasks. For example, their Orders Agent processes 5,500 truckload orders per day and saves 600 hours of labor daily.

Want to see AI agents transform your workflow like C.H. Robinson?

We'll help you build custom AI co-pilots for your toughest challenges.

Alina

Client Manager

Challenge 3. Poor experience drives customers away → seamless UX keeps them loyal

Back in 1964, a logistics expert Grosvenor E. Plowman came up with a simple idea that would shape the entire industry. He called it the “Seven Rights” of logistics. According to Plowman, efficient logistics is when you deliver the right product, in the right quantity, in the right condition, at the right place, at the right time, to the right customer, and at the right cost.

Decades later, the idea still holds up. The only difference is that the modern world has added an eighth “Right”: the right experience. The seven Rs haven’t gone anywhere, but customers now want more. Whether they’re booking a ride or managing a global shipment, modern customers expect speed and control. Anything slow or clunky, and they click over to your competitor.

Let’s take a B2C booking experience as an example. Ten years ago, customers were fine waiting on hold to book a taxi or standing in line for a bus ticket. Today, they expect to book a ride in seconds from their phone, see where their vehicle is, and know the exact cost upfront.

So, if your app loads slowly, asks for six fields to be filled in, and takes forever to calculate the price, users will opt out.

To keep customers (= revenue), you need to modernize your legacy software or build new from scratch. Pick the one that’s closer to your soul… and your budget. Here are some core features to include in a B2C booking app:

| ✓ Instant booking | ✓ Accurate pricing before booking | ✓ Real-time vehicle tracking | ✓ Automated updates |

| ✓ Digital payments | ✓ Rating system | ✓ Trip history | ✓ One-tap rebooking |

Mind that each service type has its own must-haves:

- Taxi apps rely on dynamic pricing and driver availability.

- Bus platforms need fixed-route scheduling, seat selection, and digital ticket validation.

- Car-sharing apps require vehicle condition reporting and time-based billing.

- MaaS solutions demand seamless integrations, unified payments, and multi-modal trip planning.

The same logic applies in B2B logistics. Business clients don't have time to wait on hold or send emails back and forth. They need answers now, and self-service platforms give these answers. Instead of emailing to ask "Where's my shipment?", they check live GPS tracking and see exactly where their freight is and when it will arrive.

If your clients can manage their logistics independently, they work faster and rely on you more. Without a single phone call, they have 24/7 access to quote generation, booking confirmation, real-time tracking, delivery proof, and payment processing. That's what "the right experience" looks like today.

When people get what they need fast, they don’t search for alternatives. Riders don’t delete your app. Shippers and carriers don’t switch platforms. They stay and scale with you.

Challenge 4. Your investment might not pay off → automate what's costing you the most

Every business owner worries that a new software system might not deliver a return. And it makes sense: you invest upfront, but the payoff shows up later. These worries shrink once you know what part of your business to streamline with the new technical solution. Should you automate route planning or build a delivery app from the ground up?

The answer depends on where your business loses the most time and money.

At Stfalcon, we help our clients find that answer and build a solid business case around it. Here's how custom software development brought measurable ROI to one of our clients.

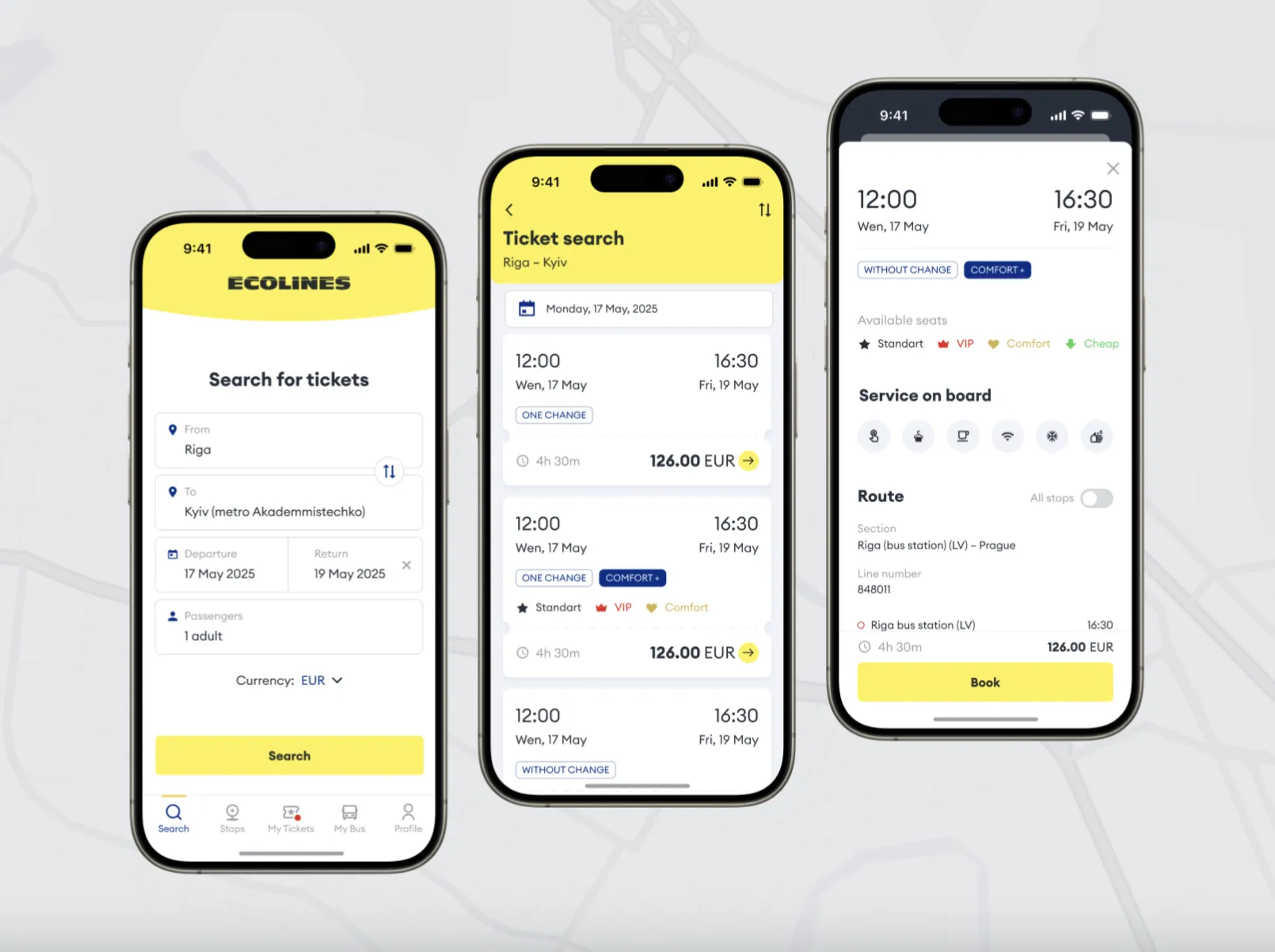

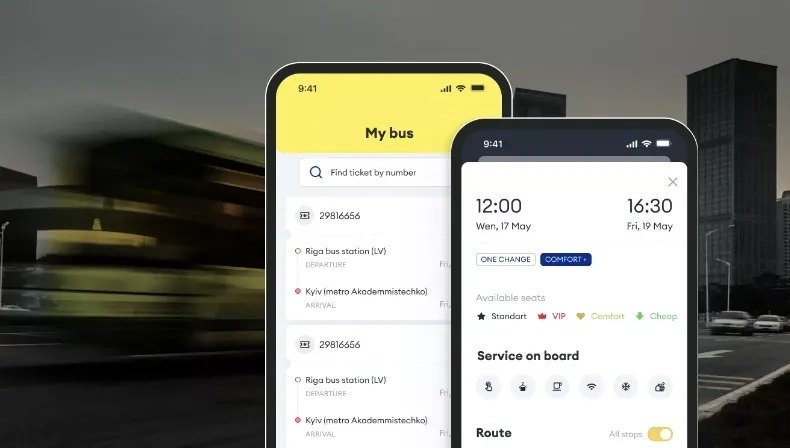

Ecolines boosts ticket sales twofold after mobile app revamp

Ecolines is one of Europe's largest coach operators. They came to us with a bus ticket booking app that was losing customers. Crashes at checkout, frozen payments, and confusing navigation drove people away.

We rebuilt the app from scratch with simplified booking flows, stable payments, and intuitive navigation. The results came quickly: conversions doubled, and Ecolines regained its competitive edge in a crowded market. Here’s the whole story if you need more details.

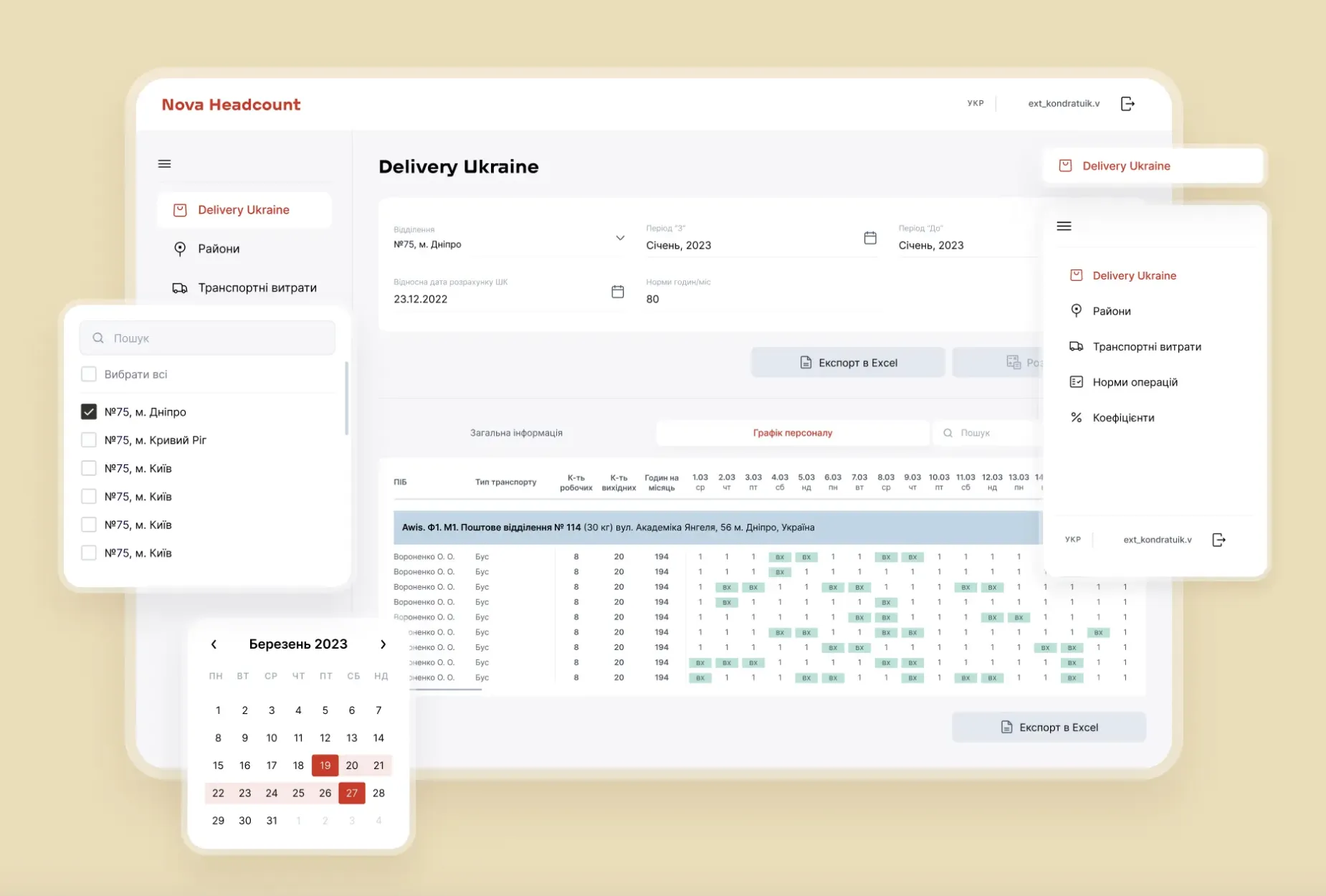

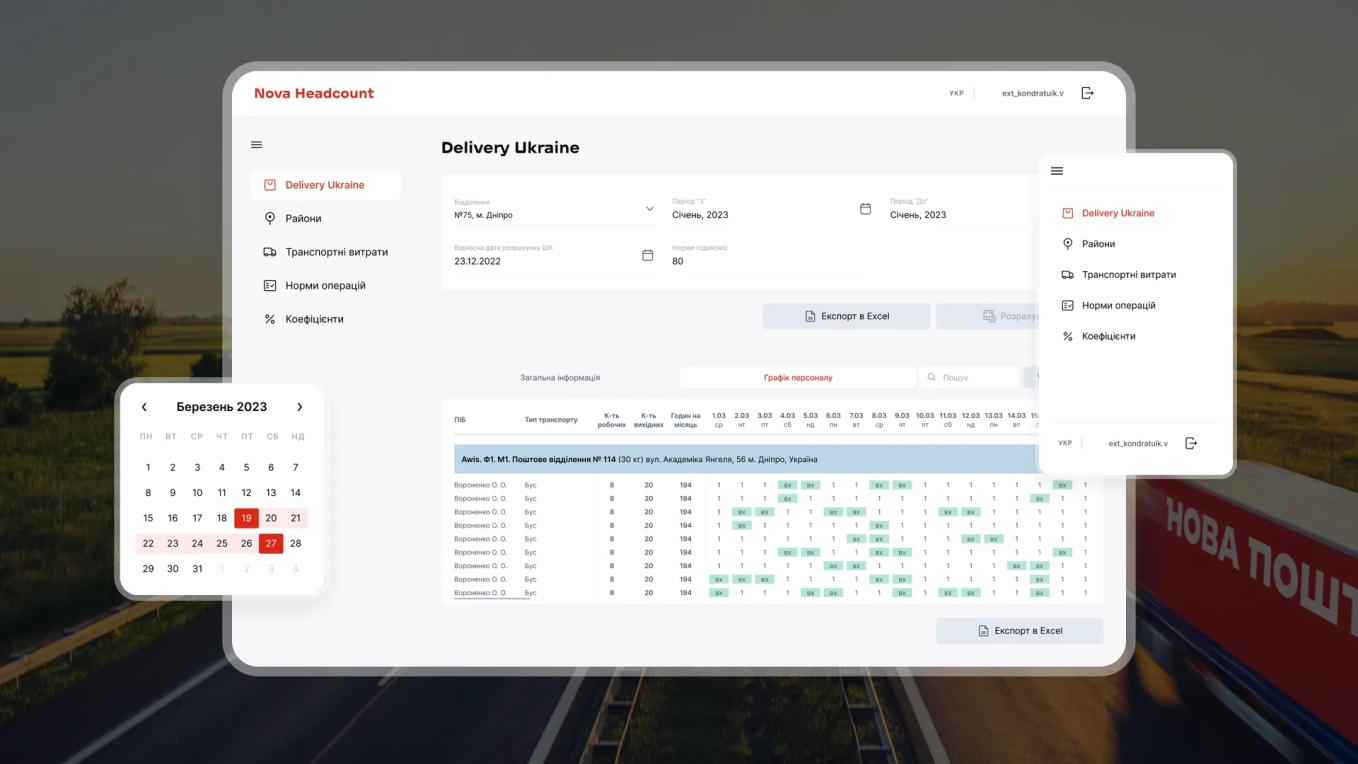

Nova Post cuts shift planning from hours to minutes

Nova Post is Ukraine's largest postal company with over 13,000 post offices and 38,000 employees. Managing shifts for that many people across the country was a nightmare. Managers used Excel sheets and guesswork to estimate staffing needs. With office occupancy changing based on location, season, local events, and delivery volume, this approach was slow and error-prone.

We helped build Nova Headcount, a custom platform that calculates staffing needs, predicts workloads, and generates schedules in minutes. It automates 99% of the manual work that managers used to spend hours on daily.

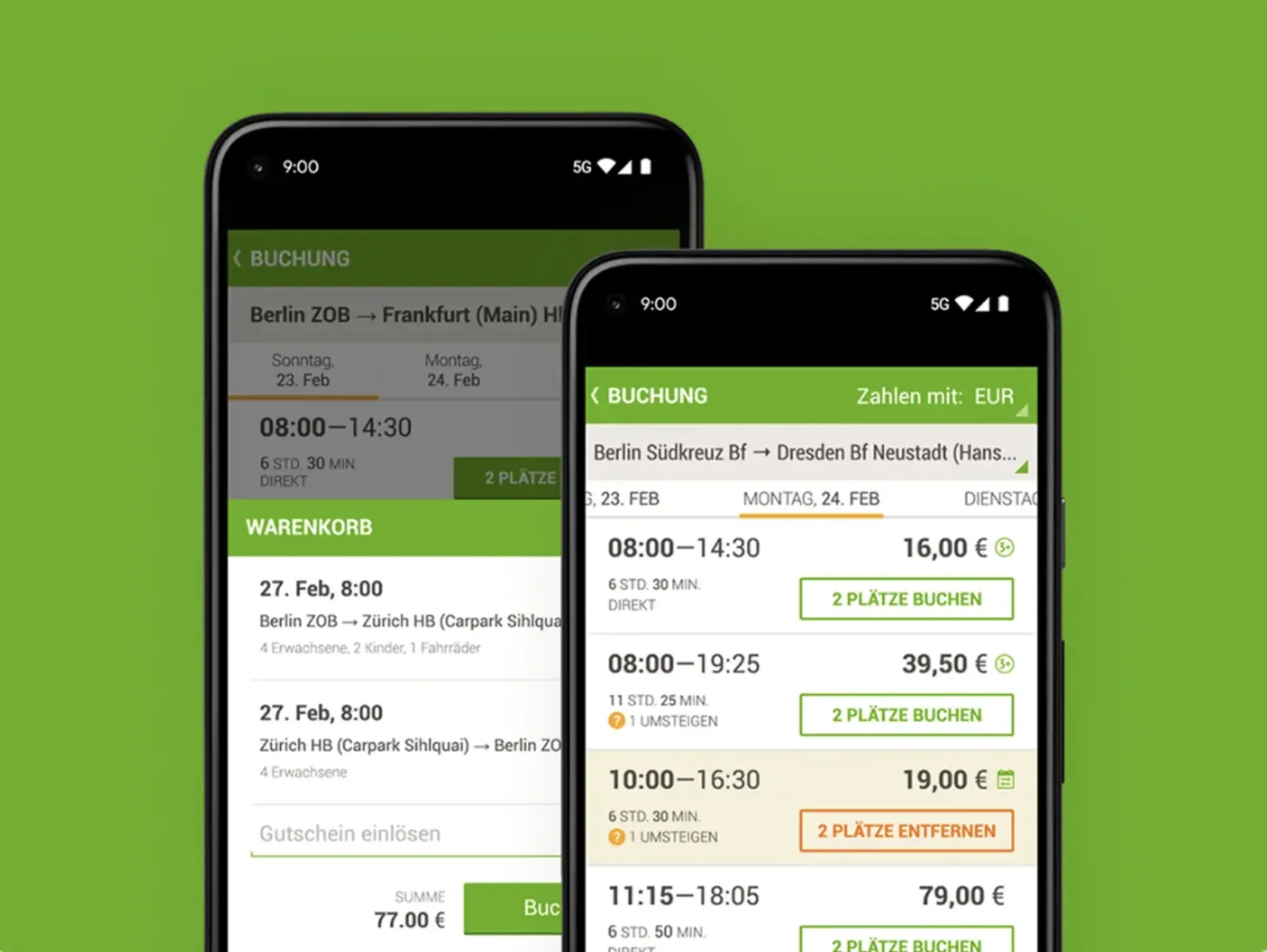

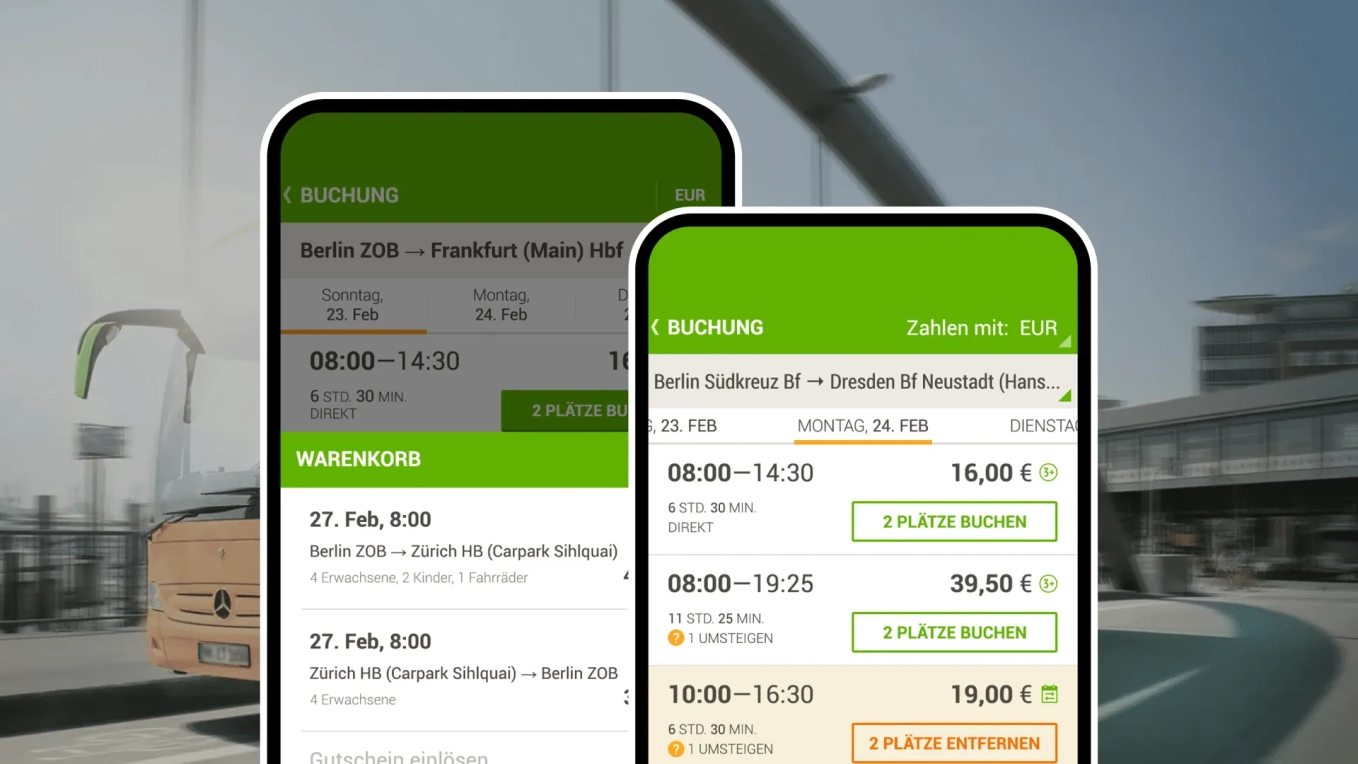

Berlin booking startup captures 40% of Germany’s bus market with its booking platform

In 2011, Germany lifted a decades-old ban on long-distance buses, opening the market for the first time. A Berlin startup saw the opportunity, but needed a platform that could handle live bookings, routing, partner integrations, and real-time data from day one. They had a product vision, and we helped them bring it to life.

We built a multi-platform ticketing system with mobile apps and partner portals designed for hundreds of routes and high traffic. Working alongside the client's developers, we handled core booking logic and integrations while they managed local payments and future iterations.

By 2014, the startup covered 38.5% of Germany's intercity bus routes. After a 2015 merger with another major operator, they controlled 73% of the market and became Europe's largest intercity bus company. Not every project is of this scale. But every project starts with the same question: what will it cost?

Supply chain challenge 5. Big tech vision, tight budget. Here’s how to make both work

Companies hesitate to invest in transportation software because they're unsure about costs. Understanding pricing depends on where you are in the process.

If you’re in the planning stage, note that price varies with three big drivers: automation level, integrations, and fleet scale.

Automation level

Are you digitizing basic dispatch or building an intelligent system that handles route optimization, predictive maintenance, and automated customer communications?

→ More automation means more complexity, but also more operational savings.

Integrations

Does your system need to connect with existing ERP platforms, carrier APIs, payment processors, GPS providers, and warehouse management systems?

→ Each integration adds development time and costs to your project.

Fleet scale

Managing 10 vehicles requires different infrastructure than managing 1,000.

→ Larger operations need more robust databases, real-time processing capabilities, and a scalable architecture that can handle peak loads without slowing down.

This won’t give you exact numbers, but you’ll know what drives the price. For specific examples, we’ve also researched costs for a parcel delivery app and an Uber-like application.

If you're already negotiating with vendors, expect rough estimates upfront. But projects rarely go as planned. Scope expands, technical challenges emerge, or integrations turn out more complex than expected. Budget overruns happen, even with experienced teams.

At Stfalcon, 16+ years in logistics and transportation have taught us how to keep costs predictable. We start with a Traffic Light Method. When a client shares their vision, we map out each feature and assign it a color:

- Green: We already have this feature prebuilt. Implementation is fast and costs are low.

- Yellow: The feature is partially built. It needs some custom development with moderate time and cost.

- Red: Custom feature that needs to be built from scratch. Requires the most development time and investment.

This approach shows you where your budget goes and helps prioritize features based on urgency and ROI. Along with pre-built modules, we implement AI-powered workflows that reduce the development time by 30% and, consequently, save your money.

When you decide on custom software development, you shouldn’t sacrifice tech excellence because of budget constraints. With more than 346+ projects delivered, we know the best solution for each use case and help you define what functionality you need now and what can wait.

Be ready when the next supply chain disruption rolls in

Red Sea closures, tariff rollercoasters, and port congestions will always be variables outside your control. But you can build a custom software system that helps you act fast and prevent breakdowns before they disrupt your operations.

Build software that keeps your business moving

Let’s talk about the challenges you’re solving right now.

Alina

Client Manager

At Stfalcon, we've spent years building for the logistics and transportation industry. We understand carrier contracts, compliance requirements, and the operational realities that generic developers miss. Book a call to explore your use case.

Read the full case study

Read the full case study

Read the full case study

Read the full case study

Read the full case study

Read the full case study