Discovery Phase for a Mining Company

– Thousands of tons of minerals are extracted and delivered to ports by hundreds of trucks every day. Loading & unloading queues are crucial for maximizing performance. And we know how to optimize them with the help of a reliable equipment tracking app.

Task

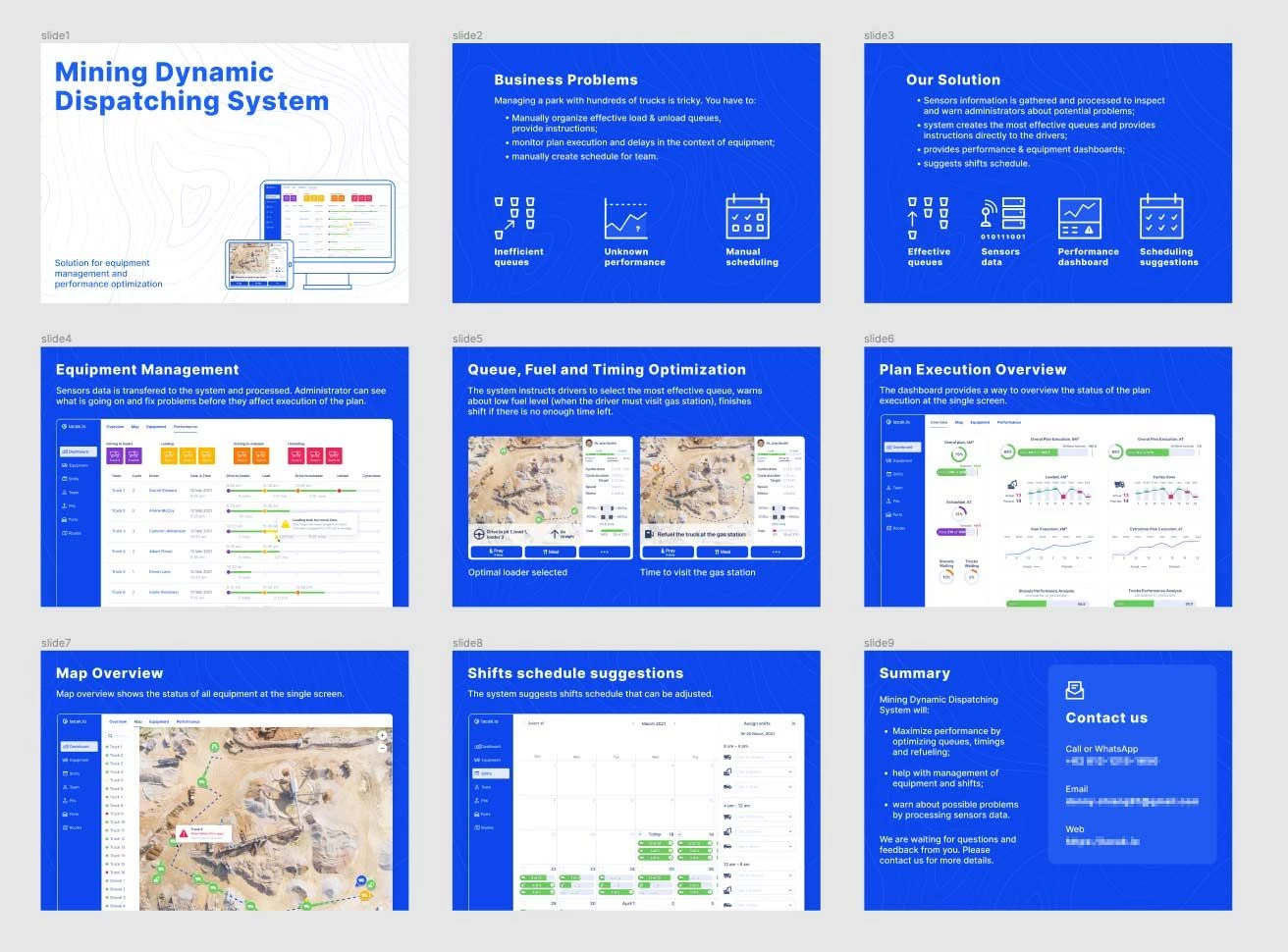

Сlient requested a complex system (mobile application and web dashboard) to track equipment status and optimize queues. Sensors are used to gather truck parameters and are processed automatically. Dashboard warns about all potential problems and sends direct instructions to the drivers.

This marked the start of the discovery phase for the mining company — a critical step toward building a fully integrated digital solution.

Solution

We started with the deconstructing of extraction and delivery processes, business model, and weak points in the existing solutions. In this case research process consisted of:

- Lean Model Canvas

- CJM of main flow for administrator and driver

- Prototypes of web dashboard and tablet mobile application

- Presentation for investors

- Product vision

- User stories

- Estimate

Regular calls with product owners allowed to gather all needed information in one place using visual collaboration platform Miro. Each iteration provided more details about the project and continus feedback.

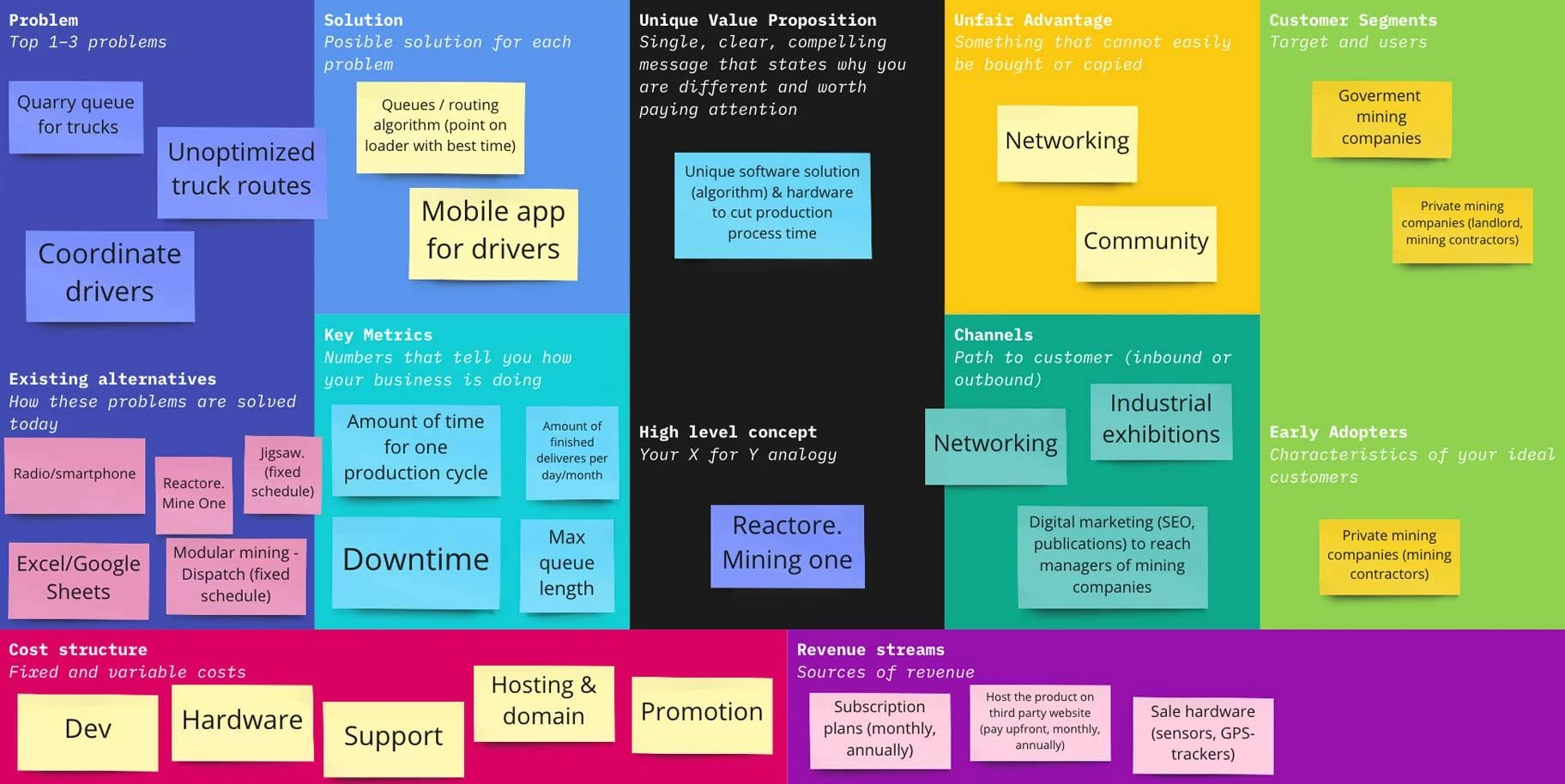

Lean Model Canvas

Lean Canvas was used to deconstruct the project structure and understand the key assumptions. It replaces usual business plans with a single page business model. Lean Canvas focuses on problems, solutions, customer segments, key metrics, and competitive advantages to form an unique value proposition. Discovery phase for mining software projects and uncover critical business and user insights.

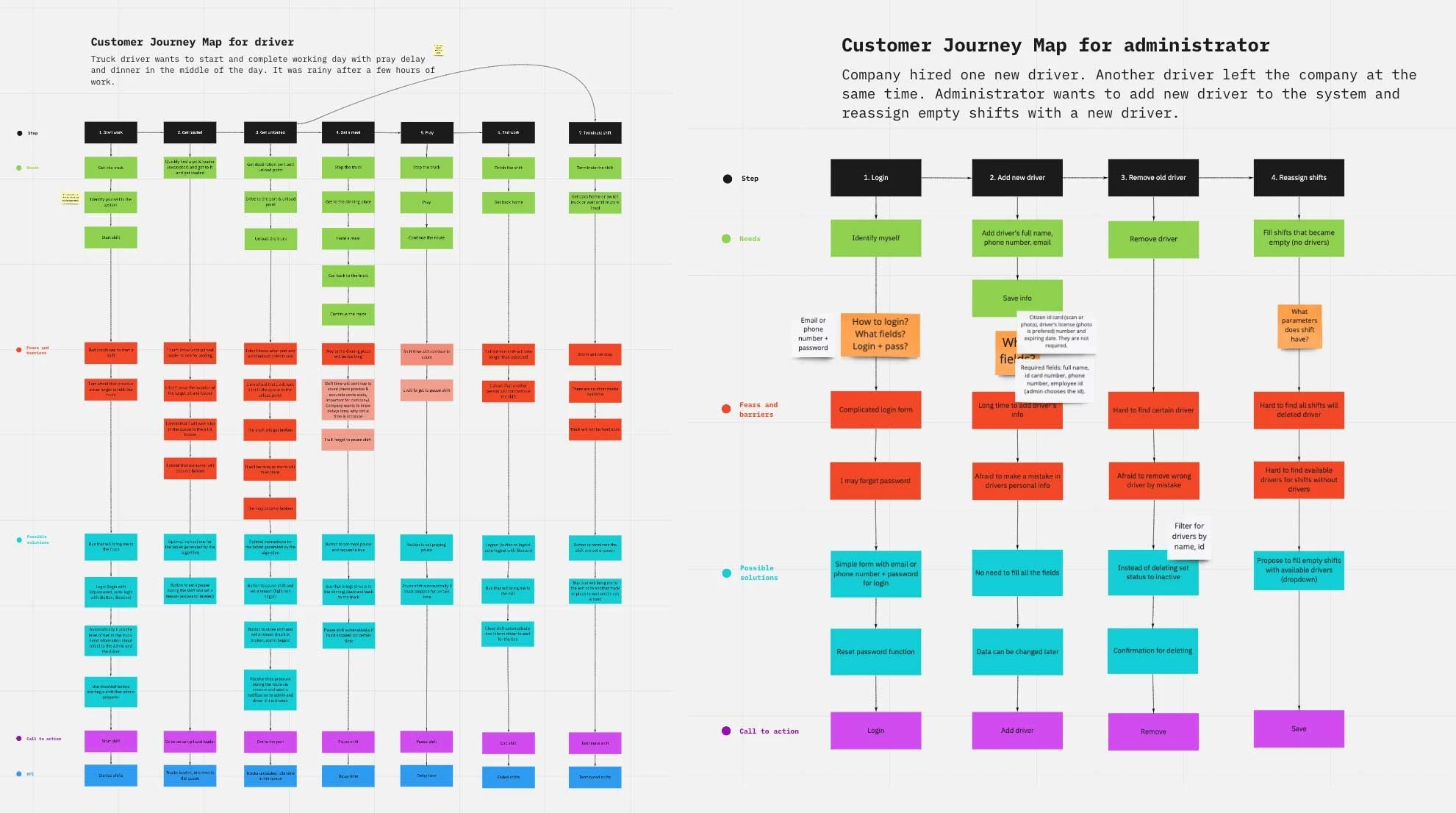

CJM

Each customer has it's own motivation, aims, needs and fears while using a product. Customer Journey Map helps to understand user on each stage of the process. We defined one scenario for each role:

- Administrator wants to add a new driver to the systems and replace another driver who left (and reassigning all the shifts) because of vacation;

- truck driver wants to start and complete working day with pray delay and dinner in the middle of the day.

Driver flow

During CJM we found out a lot of useful information, that we must take into account:

- As the most of the population at Indonesia preaches Islam we should foresee a way to pause a delivery by the driver

- Trucks can't operate during rain and storm

- Sensors allow to determine all stages of the loading and unloading process, which may be useful for automation via an equipment tracking solution

Administrator flow

Besides monitoring overall status of the equipment and checking performance metrics, administrator has to manage new workers and update the shifts schedule. That is accomplished by dashboard web application that also functions as part of the equipment tracking app infrastructure. During the research we found that:

- Scheduling process takes a lot of time

- Workers assigned to shifts may experience overlaps, that should be checked for each shift

- Shifts assigning should be automated to avoid mistakes

Prototypes

Based on the CJMs we created 2 prototypes: dashboard web app for administrator and mobile tablet app for driver. At the same time manager prepared product vision and user stories. Frontend, backend and mobile developers joined the process a bit later to do technical review.

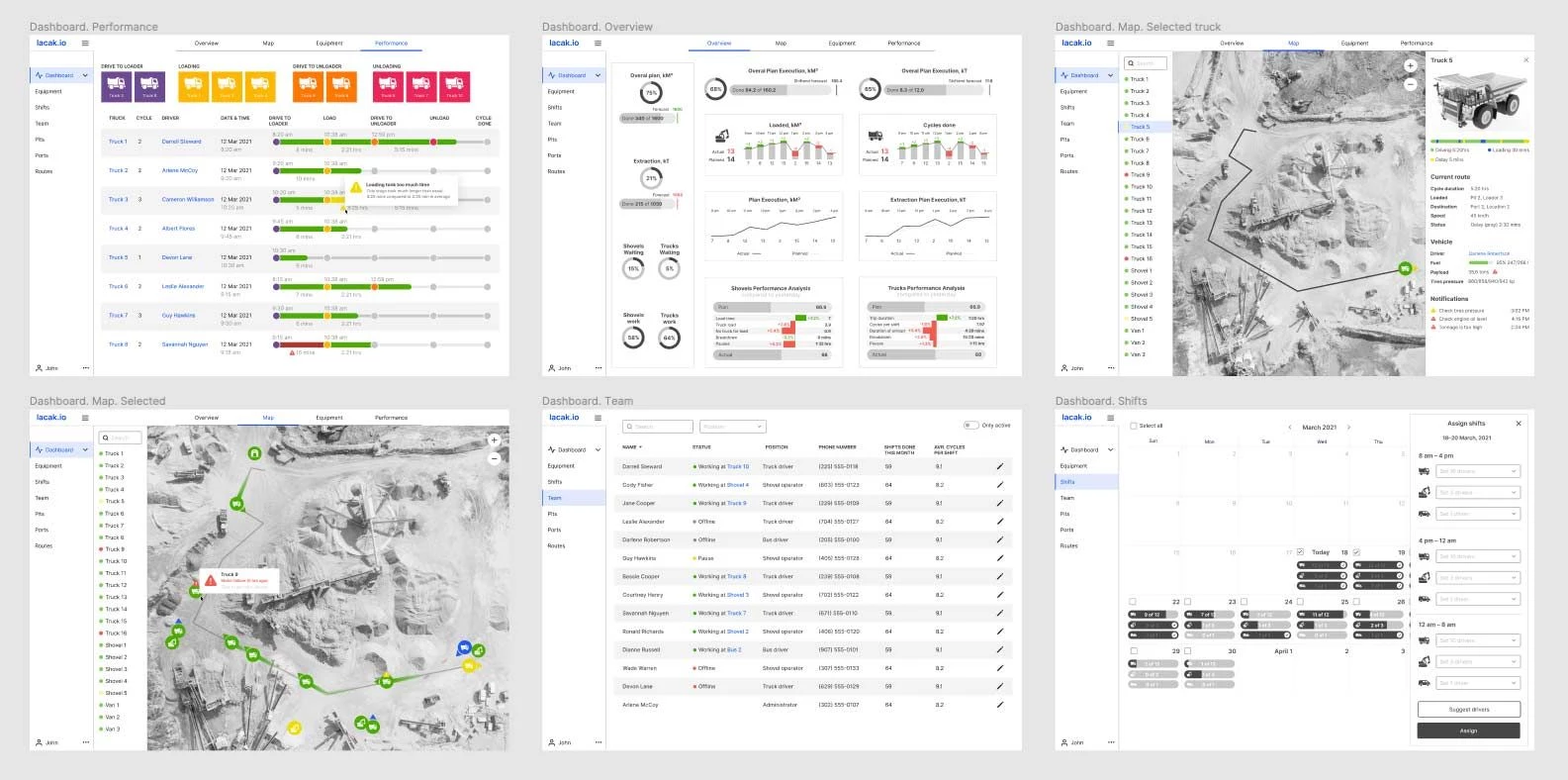

Dashboard web app

Prototype covered all main features including:

- Performance & equipment dashboards

- Map overview of the shift

- Management pages for team and shifts with auto suggestions

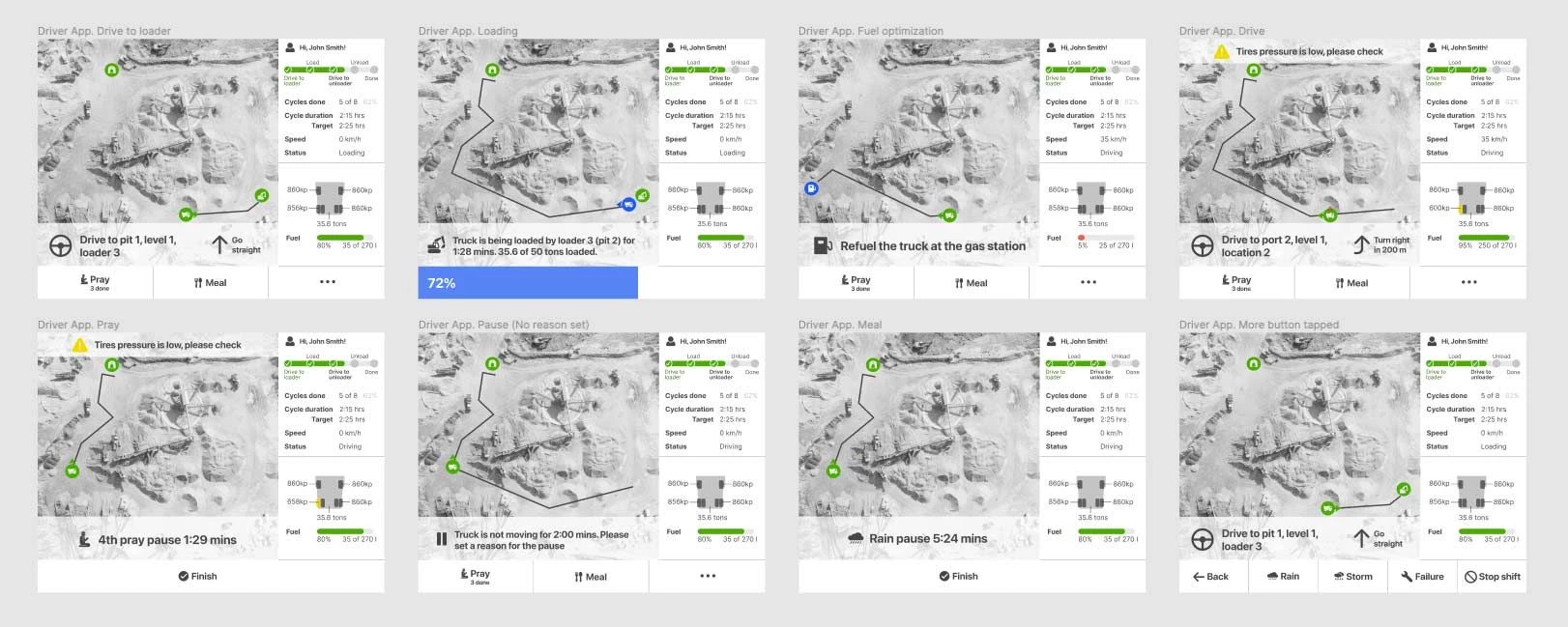

Tablet mobile app

Driver app provides direct instructions for each driver by the system. Also, it is helpful to:

- Pause shift because of pray, dinner, rain, storm etc.

- Report equipment failure

- Get notified about equipment status via an integrated equipment tracking solution

Presentation

Client requested presentation materials for the potential investors to highlight all main features and key benefits of the equipment inventory tracking capabilities and automation potential.

Result