Containers stack higher, routes redraw overnight, and freight rates behave like crypto charts. Somewhere in the middle of it all, a logistics manager fills in Excel tabs and prays the formula doesn’t break before the next shipment goes out.

At Stfalcon, we’ve spent 15 years in logistics and transportation. And trust us, plenty of teams still operate like that and rely on spreadsheets. Others have tried to move forward with off-the-shelf Transportation Management Systems (TMSs), but the story we hear again and again is the same: generic software bends the workflows to fit its logic.

There’s no shortage of TMS solutions packed with features, but efficiency today demands something built for you, not everyone. Below, we’ll show how to build a TMS around your operations. But first, let’s clarify where the market solutions fall behind.

TL;DR

Most off-the-shelf TMSs don’t fit unique logistics operations. So you have to build one that does. In this article, you’ll discover:

- What a custom TMS can do, from order management to real-time tracking and analytics.

- Which integrations matter most, including ERP, WMS, CRM, and IoT systems.

- How to build a custom TMS software step by step, plan costs, and scale with your business.

- How AI can automate workflows, optimize routes, and cut manual effort.

What’s on the market (and why it still might not fit you)

If you google for the best TMS platforms, you’ll probably come across Oracle, SAP, Blue Yonder, or MercuryGate. We won't dive deep into feature comparisons or exhaustive pros-and-cons lists, as that’s the topic of our other article.

Here, we’ll just say that the solutions you’ll find promise global reach, multi-mode support, and deep optimization. But they're designed for massive enterprises with sprawling supply chains. You get features you’ll never touch, while the ones you need aren't there.

So yes, plenty of TMSs exist, but not the one that fits the way you work perfectly. Try adapting them to your business, and you’ll quickly face friction. The simplest way to avoid that headache is to build a custom system that fits your network, partners, rules, and data model.

Automate your logistics operations with a custom TMS

Let’s build your AI-powered TMS solution today

Alina

Client Manager

What a custom TMS can do

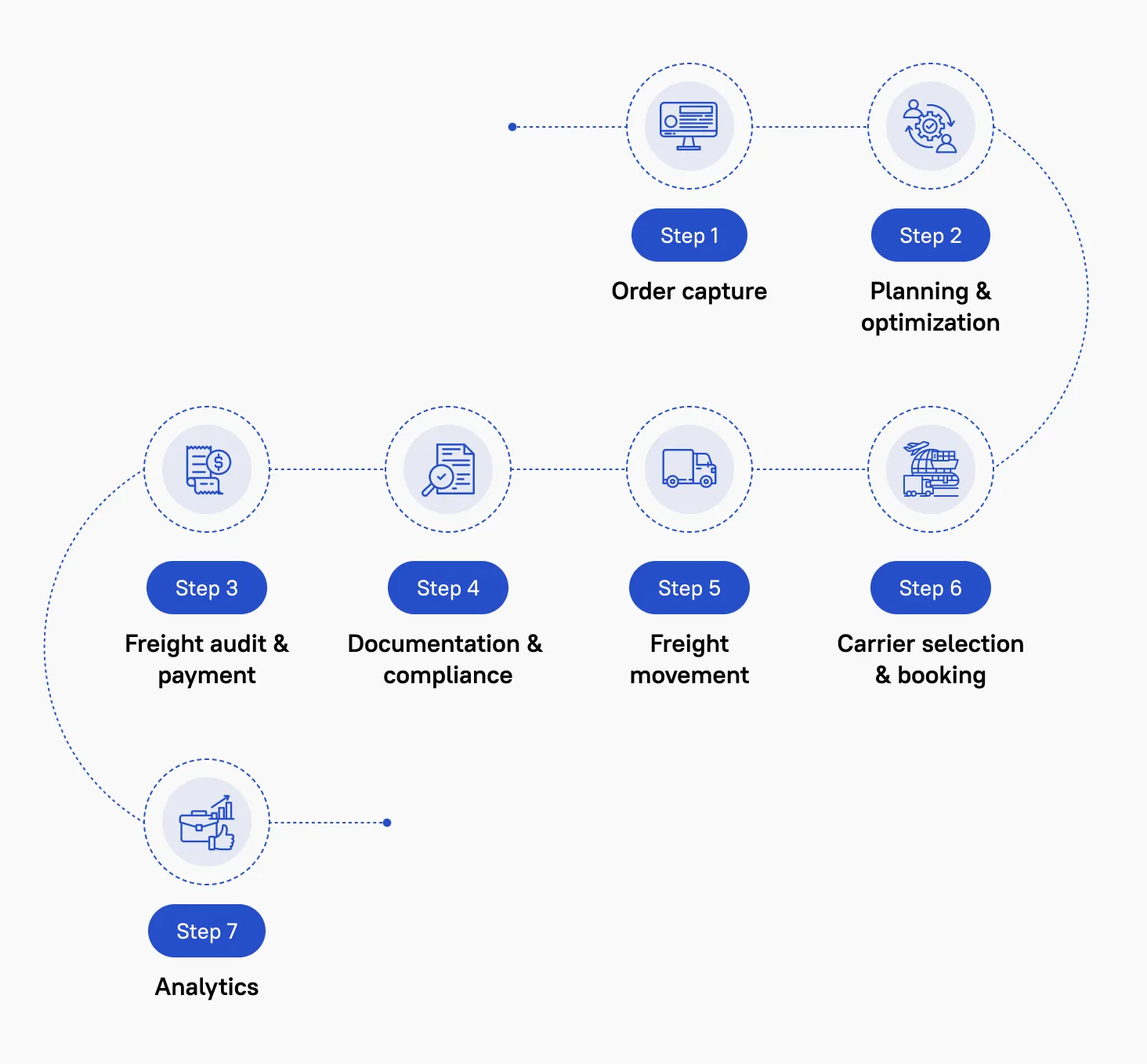

A TMS connects planning, execution, financial settlement, and performance analysis into one continuous flow. Here’s how it looks:

- Order capture → Orders come from ERP, WMS, or directly from customers. A TMS receives all shipment details: origin, destination, weight, dimensions, special handling, and delivery windows.

- Planning & optimization → A TMS evaluates routes, carriers, modes (road, rail, air, ocean), and cost options. It can optimize for lowest cost, fastest delivery, or service-level priorities. With AI/ML, TMSs can predict delays, optimize load consolidation, or select alternative routes.

- Carrier selection and booking → The system recommends or automatically selects the best carrier(s). Booking and scheduling are confirmed with carriers via EDI (Electronic Data Entry), API, or manual entry.

- Freight movement → A TMS tracks the shipment in real time, updating status from pickup to delivery. Alerts for delays, exceptions, or compliance issues trigger notifications for stakeholders.

- Documentation & compliance → Generates bills of lading, customs documents, and carrier contracts. Ensures regulatory compliance for international shipments.

- Freight audit & payment → A TMS verifies invoices against contracts and actual shipment data. Identifies discrepancies, validates charges, and initiates payments to carriers.

- Analytics & continuous improvement → The system provides reports and dashboards on KPIs: on-time delivery, freight costs, carrier performance, and route efficiency. Insights feed back into planning for future shipments.

It’s clear from the flow that a TMS doesn’t work on its own. It connects to the systems that manage orders, inventory, and customer data, and then feeds shipment results back to keep everything in sync. Not every integration is necessary for every company. When you build a custom TMS, you include only the connections your business needs. And pay only for those.

Integrations your TMS might need. Or not

The right integrations depend on how your business runs. A 3PL managing hundreds of clients' needs alternative connections than an enterprise shipping its own products. Here's the difference between having integrations or not, so you can decide what's overhead:

| Integration | Description | With integration | Without integration |

|---|---|---|---|

| ERP | Central system for orders, inventory, and finance. | Automated sales order import, freight cost updates, invoice synchronization. | Orders, costs, and invoices are entered and reconciled manually in spreadsheets. |

| WMS/YMS | Manages warehouse operations, inventory, and yard logistics. | Real-time inventory updates, automated dock and carrier scheduling, shipment status updates. | Manual coordination of inventory, dock scheduling, and shipment confirmation. |

| CRM | Stores customer information, agreements, and service-level requirements. | Customer agreements (delivery windows, handling, preferred carriers) are automatically applied. | Risk of overpromising. Account managers manually track shipments and customer requirements. |

| SCM | Provides supply chain visibility, forecasting, and sourcing insights. | Transportation lead times, capacity constraints, and landed costs feed into demand forecasting and procurement. | Planning is less accurate. Forecasting and sourcing decisions rely on estimates and manual calculations. |

| Telematics/IoT | Provides real-time vehicle tracking and operational data. | Real-time vehicle tracking, ETA updates, driver compliance monitoring. | ETAs, delays, and compliance are tracked manually. Higher risk of errors or violations. |

| Freight marketplaces | Connects to external carriers to find additional transport capacity quickly. | Spot capacity sourcing, bid comparison, automated carrier booking. | Finding extra capacity requires manual outreach, quotes, and scheduling. |

The integrations and workflows above show what's possible with a custom TMS. But do your operations need one? The answer depends on your role in the supply chain.

Who needs a TMS

Any organization that moves goods, manages shipments, or coordinates complex logistics can simplify processes with a TMS. These include:

- Shippers (manufacturers, CPG companies, e-commerce, retail, pharma, and food & beverage businesses) → plan shipments, optimize routes, and control freight costs.

- Logistics providers (3PLs, 4PLs, brokers, and freight forwarders) → manage multiple clients, coordinate carriers, and ensure service-level compliance.

- Carriers (truckload (TL), less-than-truckload (LTL), parcel, intermodal, and drayage carriers) → optimize fleet utilization, track shipments, and manage billing.

- Distributors & wholesalers → coordinate deliveries, manage inventory flow, and improve on-time performance.

- Public sector (government agencies and organizations involved in humanitarian aid, healthcare, or defense logistics) → coordinate complex supply chains, ensure compliance, and track critical shipments.

If you’ve made it this far, you're sure you need a custom TMS. Now the question shifts to how to build it.

How to build TMS software that fits your logistics

The decision is made, now what? On paper, the TMS development process looks simple: define requirements, design interfaces, build features, test, deploy. But the first step happens before any code gets written.

Step 0. Pick the right delivery partner

Not every software team knows freight and logistics. You need developers who understand LTL, intermodal drayage, and why a few hours of delay can lead to compliance violations. Stfalcon does.

Over the past 16 years, we’ve built solutions for bus ticket booking, taxi apps, order and delivery apps, supply chain, and fleet management.

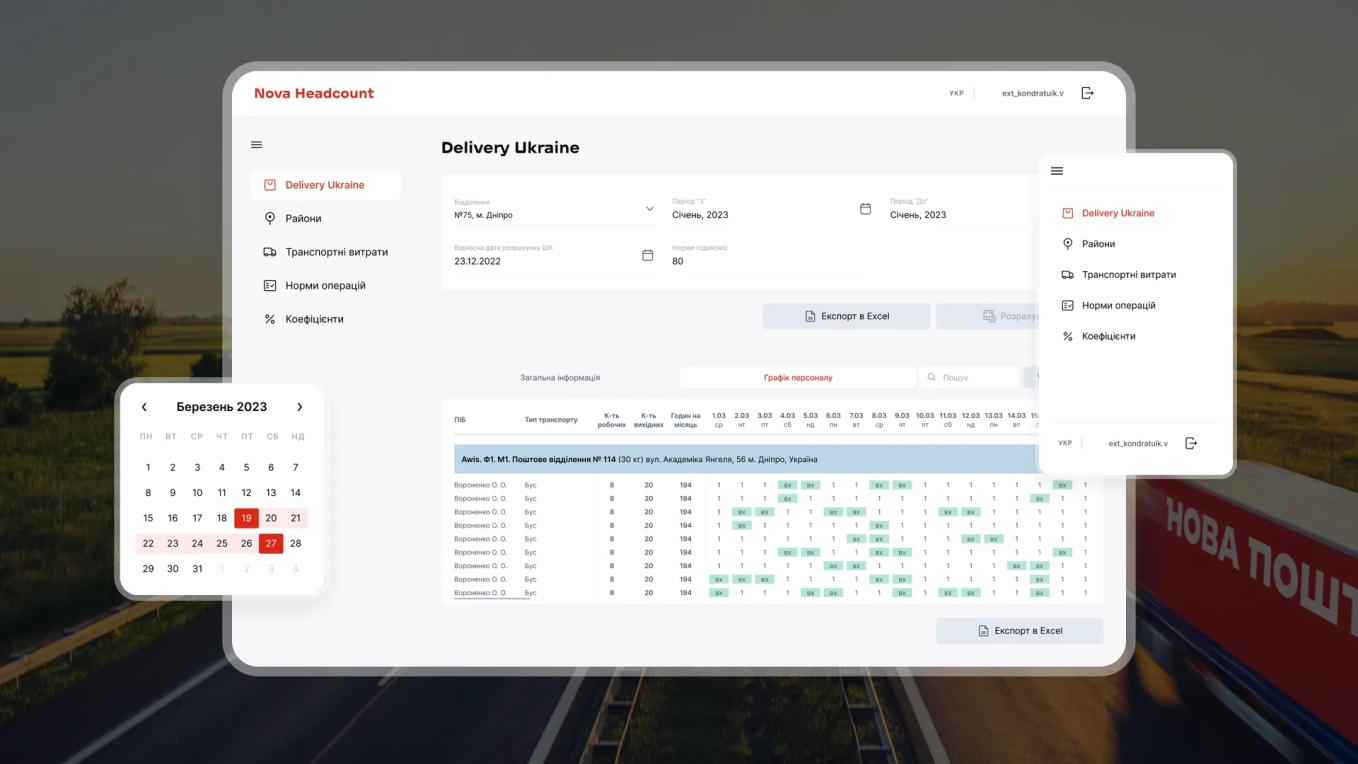

We’ve completed more than 364 successful projects, including Nova Poshta, Ukraine’s leading express delivery service. We’ve helped this company build a staff scheduling system that automates 99% of manual work.

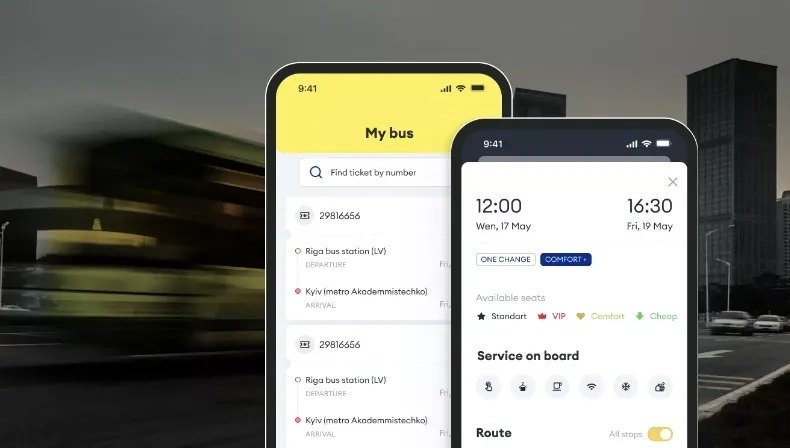

We’ve also partnered with one of Europe’s largest and most experienced coach operators, Ecolines. They had an app, but the flows were clunky. Users opened it, browsed routes, then left without buying tickets. We helped Ecolines overhaul the system and double ticket bookings.

We use technology stacks proven for transportation challenges and avoid common implementation pitfalls. Our team delivers the right solution on the first try without costly rewrites or budget overruns. And as we are not new to TMS software development, we use pre-built logistics modules and AI workflows that accelerate development by 30%.

No matter if you pick Stfalcon or another partner, the team must understand logistics. Only then can you move to the next step.

Step 1. Define TMS requirements

Before design or development, you need clarity on how your operations work today and where things break down. You should document the workflows, exceptions, and business rules that make your operations unique. Here’s how it looks step by step:

- → Map your current processes: Trace how shipments move through your system today, manual handoffs included. Identify where delays happen — for example, manual data entry or communication breakdowns between teams. These bottlenecks reveal where a custom TMS delivers the most impact.

- → Document your specific needs: Generic TMS platforms assume standard cargo and delivery models. Your operation doesn't. Do you handle temperature-sensitive goods, oversized freight, or hazardous materials? Are you local, national, or crossing borders with multi-currency and customs requirements? Does your industry require specific compliance (food safety, dangerous goods)? These details dictate which features are essential for your TMS.

- → Identify integration points: Your TMS needs to connect with existing systems, like ERP, WMS, CRM, or any other tools you use. Map these connections early to avoid data silos and duplicate work later.

- → Plan for scale: Will shipment volume double in three years? Will you expand into new regions or modes? Design for growth at the beginning, so the system evolves with your business.

- → Define user roles: Dispatchers, managers, finance, and drivers don't need the same access or tools. Establish who sees what data, who can edit shipments, and what approval workflows need enforcement.

Remember to document everything: user stories, workflows, and functional specs. Clear requirements prevent scope creep and unnecessary delays.

Step 2. Choose the right technology stack

The technology you choose affects system performance, development speed, and how easy it is to maintain long-term. There's no universal “right choice,” but every tech decision should address a few critical questions:

- Can it scale? It’s easy to forget about scale when operations run fine. But what happens when your volume triples or when you start shipping across borders? A cloud-native TMS built on AWS, Azure, or Google Cloud and microservices adds capacity without rebuilding the core system.

- Is it secure? You’re dealing with sensitive shipment data, customer records, and financials. Choose battle-tested frameworks with robust security practices baked in.

- Can you maintain it? A bleeding-edge stack might look exciting, but can your team support it long-term? Prioritize tech that’s well-documented and has a strong community.

From our experience, the following tech stack works best for logistics software projects:

| Back-end | Front-end | Databases | Cloud providers |

|---|---|---|---|

|

PHP Symfony Node.js GoLang (for performance-heavy workflows) |

Vue.js React (for robust admin interfaces) |

PostgreSQL (for transactional data) Redis (for caching) MongoDB (for flexibility with semi-structured data) |

AWS Azure |

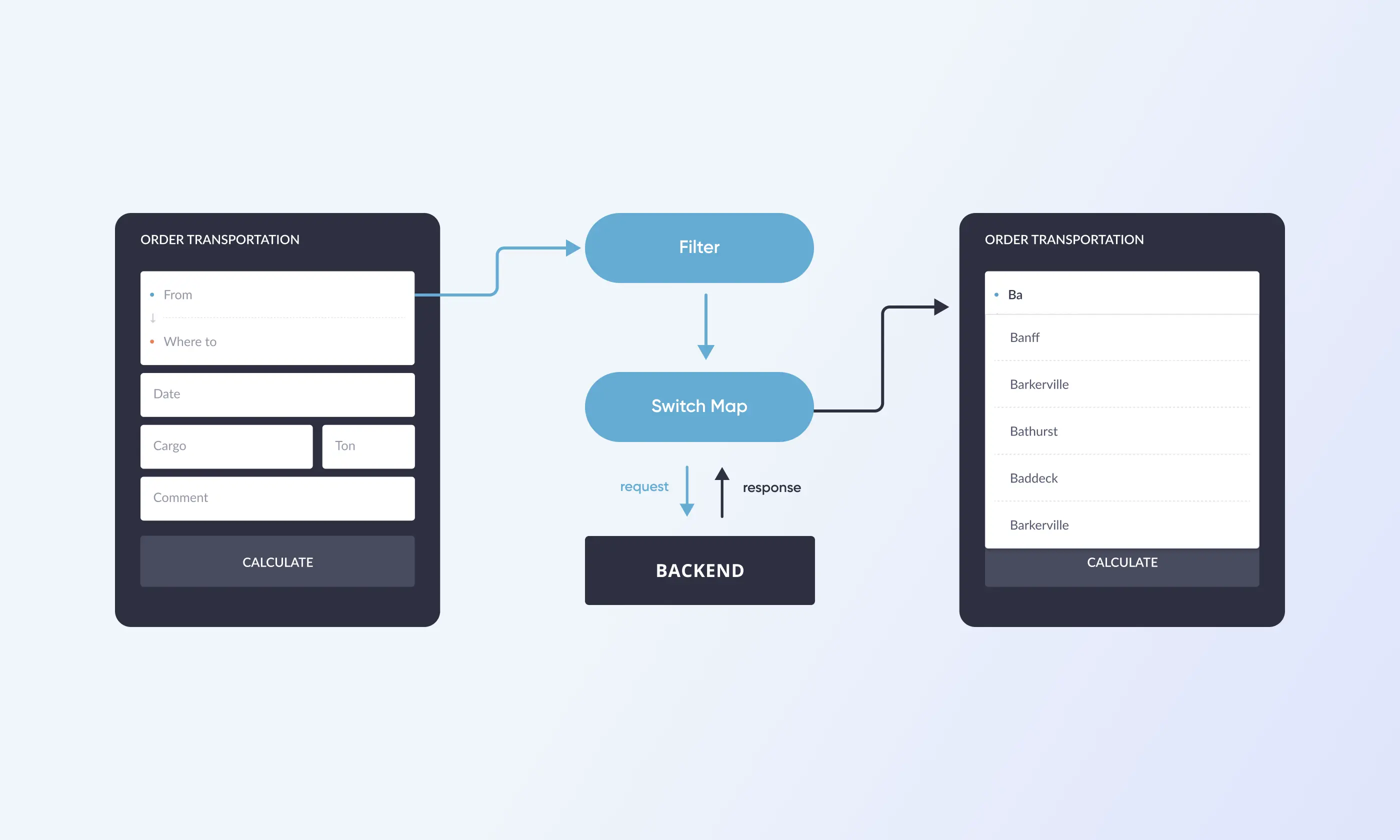

In one of our projects, we used PHP Symfony to build the core logic of the system. It handled all main business operations and data processing. The interface had many complex elements, so our front-end team used Vue.js and RxJS to make it fast and responsive.

Step 3. Create a UI/UX design

TMS users don’t have time to fumble through confusing screens. That’s why you should design an easy-to-navigate interface that provides critical information in one place. Focus on dashboards with key metrics, simple workflows for order management, and real-time tracking that users can access at a glance. Your system should be user-friendly for everyone on your team.

Here are some guiding UX principles we apply to logistics systems:

- → Clear navigation: Users should always know where they are and how to get back.

- → Efficient data entry: Use autocomplete, pre-filled defaults, and bulk actions wherever possible.

- → Actionable dashboards: Prioritize what users need to see and do right now. Status alerts, pending actions, and shipment exceptions should be front and center.

- → Responsive design: Many dispatchers and field users check updates from tablets or phones. Take it into account while creating a design.

With a clear design in place, the next step is to bring it to life.

Step 4. Develop core modules and test

Every custom-built TMS is distinct, but most share a common backbone of essential modules. They are developed based on the specific needs identified during your requirements phase.

Here's what most logistics operations can't function without:

| Order management | Tendering | Shipment rate management |

|---|---|---|

| Capture shipment requests from customers, ERP systems, or e-commerce platforms. Validate addresses, consolidate orders, and route them to the appropriate fulfillment process. | Send shipments to multiple carriers for bids, compare offers automatically, and select the best match based on cost, transit time, or service level. | Store and manage carrier contracts, accessorial charges, fuel surcharges, and regional rate variations. Calculate accurate freight costs in real time based on shipment details. |

| Load planning | Fleet management | Connectivity portals |

| Optimize how freight gets consolidated: group shipments by route, destination, or delivery window to maximize trailer capacity and minimize costs. | Track vehicle availability, driver assignments, maintenance schedules, and hours-of-service compliance. Essential if you operate your own trucks. | Provide self-service access for customers (track shipments, request quotes) and carriers (accept loads, update status, submit invoices). |

| Dock scheduling and yard operations | Tracking, tracing, and event management | Business intelligence and analytics |

| Assign dock doors, manage carrier appointment windows, and track trailer locations in your yard. Prevents congestion and reduces carrier detention charges. | Monitor shipment location and status in real time via GPS, telematics, RFID, or carrier APIs. Trigger alerts for delays, exceptions, or missed milestones. | Report on KPIs like on-time delivery, cost per shipment, carrier performance, and lane profitability. Turn operational data into actionable insights for continuous improvement. |

| Documentation management and settlement | ||

| Generate bills of lading, proof of delivery, customs paperwork, and invoices. Automate freight audit to match carrier invoices against contracted rates and catch overcharges. | ||

From our experience, you should start with the features that solve your biggest operational pain points. For many companies, that's order management, rate management, and real-time tracking. But if dock congestion costs you more in detention fees, build scheduling first. Add advanced analytics and connectivity as your operation scales.

Quality assurance and testing

When your modules are built, you need to be sure they behave as expected under every possible condition. At Stfalcon, we usually follow a multi-layered testing approach:

- → Unit testing: Developers conduct unit tests to verify that individual components and functions of the TMS work correctly in isolation.

- → Integration testing: When modules connect, we verify data flows correctly between them. This is crucial for the API integrations you've planned.

- → User acceptance testing (UAT): Your team uses the system in a staging environment with real shipment data (or close to it). Dispatchers book loads, account managers track shipments, and finance reviews invoices. Feedback from this phase drives final adjustments before launch.

This way, we help our clients prevent serious bugs and problems after the TMS is launched.

Step 5. Deploy and maintain

Next, the system moves into the live environment. If your operations are complex, it’s smart to roll it out in phases. Start with a few users or locations, fix any issues that pop up, and then expand.

Once live, the TMS requires ongoing attention. Here’s how TMS maintenance will look like if you decide to partner with us:

- → System monitoring: We use real-time monitoring tools to identify bottlenecks, bugs, or integration issues before they affect operations.

- → User support: We deploy responsive support channels, so your team has help when needed.

- → Updates and enhancements: We schedule regular update cycles to patch vulnerabilities, improve performance, and implement new features based on user feedback or changing business needs.

The roadmap is clear, but what does it take in dollars?

What drives the TMS cost

When you ask, “How much will my TMS cost?” no one can give a precise answer immediately. The final price depends on several factors, such as the software’s complexity, the number and type of integrations, the design of the UI/UX, data migration requirements, compliance needs, and many more.

Each of these elements adds to the total cost. The best way to get an estimate is to communicate your requirements to several software vendors and compare the rough cost estimates they provide.

At Stfalcon, we make costs transparent with our Traffic Light Method. We categorize all features as green, yellow, or red. Here’s what it means:

- Green: Pre-built features already in our codebase. They are fast to implement and cost-effective.

Examples: login, profile management, authentication. - Yellow: Partly reusable features that we adapt to your needs. They require some development time and have moderate costs.

Examples: payment integration, delivery module, loyalty program. - Red: Custom features built from scratch. These require a full development effort and come at full price.

Examples: advanced analytics, courier shift management, AI recommendations.

This approach shows clients exactly where their money goes. They can decide to launch faster using greens and yellows or invest in reds from day one.

If you have a project in mind, contact our team to get a feature-by-feature estimate and plan your launch based on greens, yellows, and reds.

Bottom line: Don’t just build a custom TMS. Build it with AI

A custom TMS fits your operation, connects your systems, and automates the repetitive tasks that used to consume hours. But the decisions still require people — unless you add AI copilots into the system.

Today, AI agents and co-pilots can select carriers, plan loads, optimize routes, and manage operations end-to-end. It might be hard to believe, but AI acts on real-time data and makes decisions like your manager or dispatcher — only faster and without errors. We can integrate AI agents into your TMS, so your operations adapt instantly to every change on the road.

Read the full case study

Read the full case study

Read the full case study

Read the full case study